Fertilisers are critical to today’s agricultural sector. We take a look at Biota Nutri and speak to CEO, Mark Valentine, about the growing technology that is changing farming in the Netherlands and abroad.

GROW THE BEST

Farming is a unique and ever-changing frontier. Where agriculture focuses on field-scale produce grown at ground level, horticulture revolves around the use of greenhouses and the many technological systems that are put in place to maximise growth.

Growing technology, such as fertilisers, are key to maintaining this yield and continue to play a critical role in agricultural practices at all levels. In the Netherlands, Biota Nutri (Biota) is one such company that supplies growing technology to the European market and beyond.

“The industry is quite strong in the Netherlands, which is the second biggest exporter of agricultural products next to the US according to the government figures,” begins Mark Valentine, CEO of the company. “It is an exciting sector to work in; the Dutch are known as the de facto leaders of growing technology so the competition is high at all times, which forces you to work to the highest standards.”

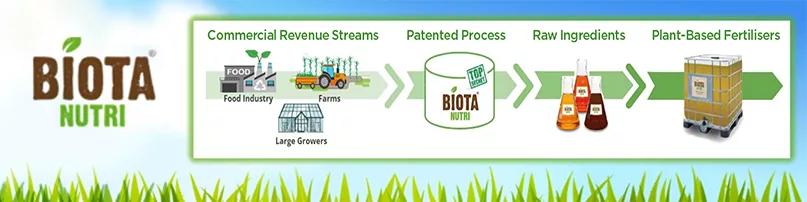

Biota develops, produces and distributes organic fertilisers for agriculture and horticulture. The company is constantly conducting R&D in the field of recovering nutrients from plant-based residual streams, with the aim to create a world in which circular and organic cultivation is accessible to everyone.

Biota has three connecting business lines; the first is the manufacturing of organic fertilisers, through which the company offers a full range of fertilisers and stimulants to suit horticultural and agricultural needs; the second revolves around the company’s growing technology through which Biota advises and works with customers on bioreactors or other equipment needed for organic growing. Lastly, Biota promotes its software tool, an online calculator that helps growers switch to organic cultivation on their own schedule.

“Biota is different from other organic fertiliser companies as we make our products from plant-based waste streams, combined with our patented process to create the basis for our fertilisers,” Valentine tells us. “Our premium products are in our Low Organic NPK range of fertilisers. They’re different from the competition in that they are clear liquids that don’t block irrigation systems, provide nutrients and trace elements immediately to the plants, and also allow produce grown with Biota fertiliser to wear the vegan trademark in the stores.”

GREEN GROWING

Despite being based in the Netherlands just outside of Amsterdam, Biota also has offices in Los Angeles in the US as well as Uganda and a presence in Canada, selling to around 30 countries with its main clients in North and South America.

The twin pillars of Biota’s focus are innovation and sustainability. According to Valentine, the Dutch government is introducing sustainability goals and looking to push farmers to grow more organic produce. These are positive initiatives, yet farmers require subsidies and assistance to adopt these changes successfully as the market demand is not as high, unlike in the US for example.

“The last couple of years under the COVID-19 pandemic and subsequent escalating energy prices have caused attrition in the industry and some businesses have closed, while others shut down in the winter as the cost of growing is too high,” he explains. “The long-term outlook is positive as the bio-based economy becomes a reality and even more green material developments are introduced.”

In light of this, Biota’s main mission is to reduce the use of chemical fertilisers by giving growers the tools they need to grow organically without compromising on quality and production. The use of residual flows plays a key role in this as by using residual streams, the company is turning plant waste into plant food to create a truly circular and sustainable model for growers.

“In the longer term, we aim to be integrated directly into the recycling and processing facilities to optimise the process and create other sustainable product options from the remaining biomass, such as clothes and furniture,” Valentine continues.

EXPANSION AND AUTOMATION

Biota has planned to open a US facility since 2019, with the goal of manufacturing on-site to reduce the costs and shipping delays for its US-based customers. However, with the arrival of COVID-19, the company altered its strategy and expanded its European capacity with a new fully automated tank farm manufacturing facility that is reproducible and scalable for future locations.

“We are now in the process of working with investors to restart the US effort, and I will be spending the majority of my time in the US in 2023 as we get the project restarted,” says Valentine. “We also have a number of other projects underway, mostly collaborating with universities or groups looking to develop advanced sustainable products or solutions. One of our main challenges is price; organic products aren’t made in the same high volumes as chemical fertilisers at the moment, so the economies of scale and optimisation are still in progress.”

Yet, according to Valentine, the future of the industry is all about artificial intelligence (AI) and automation, as technology can reach a level of repeatability and accuracy that humans simply cannot match. Much like the manufacturing industry, the use of robotics and automation will continue to grow when it comes to picking and packing.

“But for the rest of this year, we hope to get the US facility started to better serve the customers in that part of the world and also reach the second stage of optimising our patented extraction process, which will enable us to control our costs and reduce risks as we grow,” concludes Valentine.